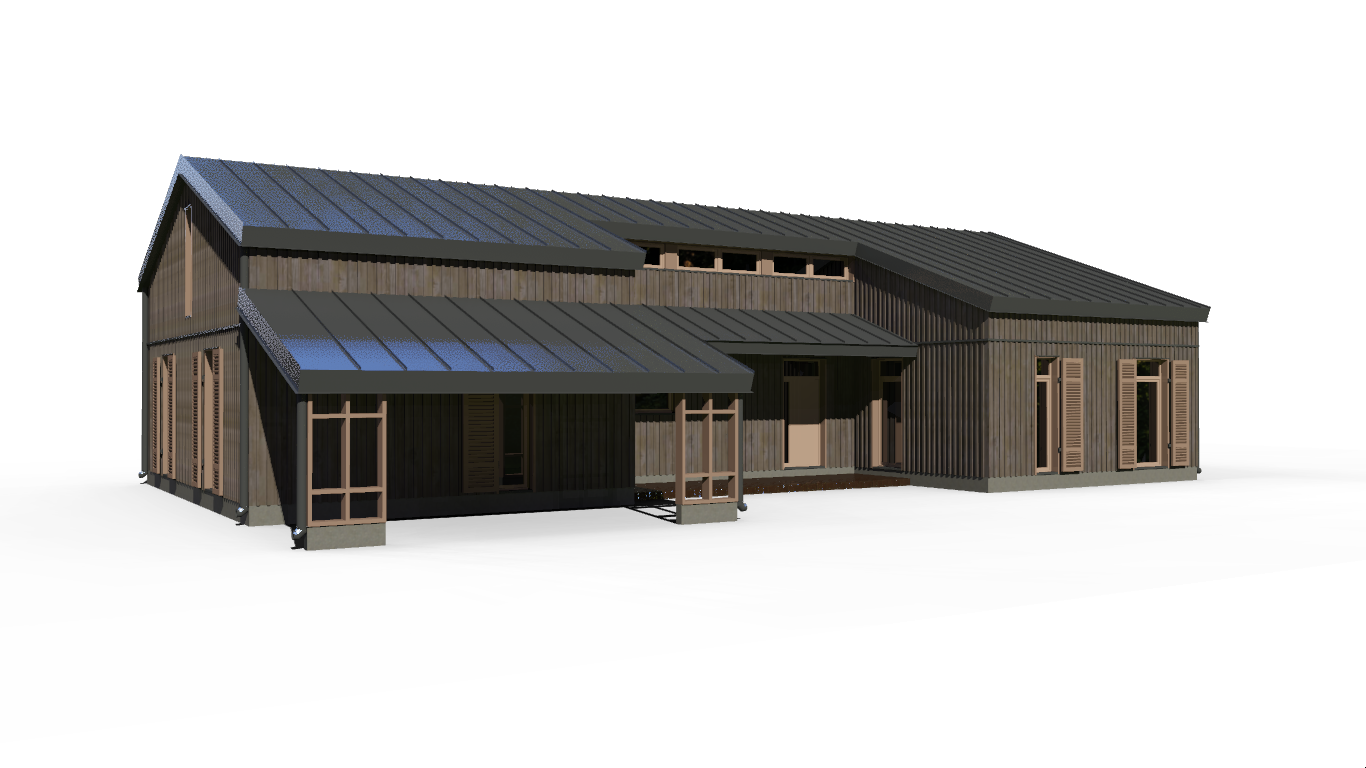

Our belief in the future of natural building materials is in line with our professionalism and experience, allowing us to create a modern house project with ergonomic design to each of our clients. We build technology-tested, pest-resistant, fireproof, sustainable and wholesome family houses.

Hemp concrete panels are manufactured using hemp that is grown and processed in Latvia, as well locally sourced lime particles and timber is used in this technology.

Our employees have more than 20 years of experience in construction. We use only the finest materials and products in the construction to provide our clients with the highest quality houses.